Here is Part 2 of Our Bug-Out Boat and the Choices We Made

Part 1 contains:

- Motorboat or Sailboat

- Monohull or Multihull

- Hull Length

- Saildrive versus Direct Drive

- Fixed, Folding & Feathering. Choosing the Right Propeller

- Diesel Engines or Electric Motors

- Electrical Power

- Water

Part 2 contains:

- Masts & Sails

- Anchors

- Engine Location

- Galley

- Tenders (dinghies)

- AIS

- Hull material. Wood, steel, aluminum or plastic

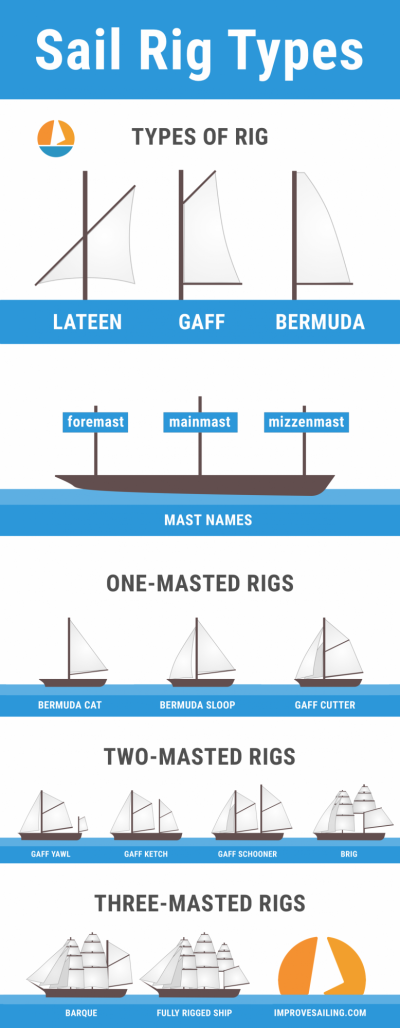

Masts & Sails

If you are purchasing a used boat, or a factory built boat, then you do not have a choice of your masts and rigs. However, if you are looking to purchase, you can always set your sights on your desired layout, and seek that out.

If you are purchasing a used boat, or a factory built boat, then you do not have a choice of your masts and rigs. However, if you are looking to purchase, you can always set your sights on your desired layout, and seek that out.

The other option is to have your boat custom built for you.

Most modern boats use Bermuda rigs. As such, you will find lots of places that can create new sails, or repair existing ones, and if you ever bring on crew they are likely to know how the sails work best.

Most boats that are under 20 meters in length will be single masted, although boats older than 30 or 40 years you can find plenty of ketch and yawl layouts.

Ketchs and Yawls both have benefits when at anchor, as they allow you to partially raise your mizzen sail, which will act as a windvane and keep the bow pointed into the wind. This can be especially helpful in an anchorage where the tide can swing you around.

If you look at older boats from the 1800s and earlier, they were all multi-masted and multi-sailed. I have seen boats of these designs flying 15 sails or more. The reason these older vessels had multiple sails is twofold. First, the material needed to create single large sails was not available. Second was manpower. In order to manipulate large sails needs a lot of manpower.

Modern sailboats have better winches allowing a single person to handle a 40 footer. Add to that powered winches, and a single person can handle a 60 footer or more.

If our boat was simply a live-aboard retirement vessel, than a single mast would be fine. If one of our powered winches fails, we order a replacement. However we are looking for a boat that can survive the end of the world. In a post-disaster world, it may not be possible to simply order a new powered winch. As such, smaller sails, and shorter masts were the way to go.

We selected a two-masted schooner. To be precise, a staysail schooner. With two shorter masts we can fly as much sail as a typical Bermuda Sloop, but each sail is smaller and easier to handle.

We have electric winches for controlling the sails, however the sails are still able to be managed by hand winching if need be.

All our primary sails are roller furling sails. Starting from the bow we have a jib, and inside that, a fore staysail. Behind the foremast we have a triangular fisherman on a roller (I've also heard this called a tri-sail... I don't know the correct name). Attached to the front of main mast is the main staysail, on a roller.

Lastly, behind the main mast is the main sail, fitted on an in-boom roller.

Some would argue that the main mast, if it's going to be a roller, should use in-mast furling. I have heard of problems with them, especially if caught in the wind, that they can jam. Should you have a sail out and it jams and can't be put away, this could lead to a very dangerous situation. Our choice of in-boom furling eliminates this issue. Even with a roller failure while the sail is deployed, we can drop the main halyard and tie down the sail.

While all the other sails are stowed on their rollers, and can be let out without having to haul them up, the main sail does need to be raised to deploy it. This is the heaviest work should the power winches fail. I can still do it... I just would prefer not to.

At the very front is a removable bowsprit. When attached we have a choice of a hank-on flying jib, or our gennaker. This removable sail has a sock to douse it before removing it. This is the only sail we have that requires two people to handle it's deployment and recovery. It's a great down-wind sail.

Anchors

There are as many opinions about anchors as there are anchors. The ones you choose will depend mostly upon your intended sailing areas.

However, it is best to have two different types of anchors. But having a secondary anchor is pointless if you're never going to use it.

Changing anchors is a major pain, and you're not likely to do it. If you have to go and grab a 50kg anchor from your locker, disconnect your primary anchor, and attach the secondary, then go and stow your primary anchor, you are likely to not bother.

That is why we opted for 2 anchors, both on their own anchor rollers, and two windlasses. We can choose to use either anchor just as easily and effectively. Having a second windlass and second length of chain is expensive, but a good plan.

It also serves as a backup if your windlass should fail. On our first boat we had a windlass fail with our anchor dropped in 50 meters of water, and learned how vital it is that you have a way to retrieve your anchor. The day it happened to us we had a pair of guys in their 20's aboard and they hand-hauled the anchor back up. It was a tough job for them... I don't think I would have managed alone.

That is why our current boat has twin anchor systems each with their own windlass.

Having a kedge anchor, ready to deploy on the back of the boat is also helpful. While it can be used to prevent swinging, our primary use of our kedge is when we are beaching the boat. Having an anchor on a strong line at the back is great for winching the boat back into deeper water.

Engine Location

Most monohulls shorter than 50' will have their engines under the stairway, while most over 70' will have an engine room.

Most catamarans under 40' will have their engines under the rear beds, and over 45' will have their own engine rooms.

Having engines under the stairs is very difficult to work on.

Having engines under beds is noisy and smelly, and difficult to work on (though usually not as bad as under stairs).

When possible, having engine rooms is preferable. They are usually roomier and easier to work in. They allow you to store oil and spare filters and parts where they will be needed. They are usually better soundproofed. They can also be used for other machinery such as generators, heat/air units, watermakers, and such.

Whether you have engine rooms, or just compartments, you must be able to service your engine inside and out of the weather. This is mandatory!

I have seen quite a few boats that have taken one cabin near the engines and removed the bed and converted it into a workshop, complete with drill press, welder, and even a lathe. This is something you should consider. While we opted against this, it is a good idea, especially if you are handy.

Galley

On a monohull, your galley will always be in the hull. And so it should be. With monohulls rocking side to side, the lower the galley is, the less rocking there is.

In a catamaran, you have the option of having the galley down in the hull, or up in the salon. We have found that there is less motion sickness when cooking underway, if your galley is in the salon. This also helps with there being plent of natural light from the large windows. Finally, having the galley in the salon allows conversation between the cook and the rest of the crew.

Tenders (dinghies)

As you travel on your sailboat, you will see that nearly every boat has a RIB (rigid inflatable boat). And when you talk to people who have been sailing a while and ask them what their first failure is, it's always the RIB. And what did they do? They went out and purchased a new RIB. And then complained about it.

The material used in RIBs simply does not hold up in the tropical sun. As a result, RIBs have a lifespan of up to 5 years or so. That can be extended somewhat by adding "chaps". This is a UV resistant fabric that covers the inflatable tubes to protect them from the harsh sun.

The alternative is to get a tender that is not an inflatable. For the few people who choose this route, they usually go with aluminum rowboats. Aluminum boats can mark and damage your sailboat when (not if, but when) you bump them. This is the primary reason people select RIBs as they do little damage when bumped against your hull. Aluminum boats will also sink if they get swamped by a stray wave. Again, that's a matter of when, not if, because it will happen.

But there are lightweight fiberglass boats available. These boats will float even when swamped, and they have a built-in rub rail to prevent damaging your sailboat hull. They are unsinkable, have more storage space than similar sized RIB, and will last forever.

AIS

The Automatic Identification System (AIS) is an automatic tracking system that uses transceivers on boats and ships. AIS information supplements marine radar, which continues to be the primary method of collision avoidance for water transport.

Information provided by AIS equipment, such as unique identification, position, course, and speed, can be displayed on a screen or an electronic chart display and information system (ECDIS). AIS is intended to assist a vessel's watchstanding officers and allow maritime authorities to track and monitor vessel movements. AIS integrates a standardized VHF transceiver with a positioning system such as a Global Positioning System receiver, with other electronic navigation sensors, such as a gyrocompass or rate of turn indicator. Vessels fitted with AIS transceivers can be tracked by AIS base stations located along coast lines or, when out of range of terrestrial networks, through a growing number of satellites that are fitted with special AIS receivers which are capable of deconflicting a large number of signatures.

The International Maritime Organization's International Convention for the Safety of Life at Sea requires AIS to be fitted aboard international voyaging ships with 300 or more gross tonnage (GT), and all passenger ships regardless of size.

On private yachts, AIS is optional, but highly recommended. You have the option of fitting an AIS receiver, or an AIS transciever.

There are online AIS trackers available at https://www.marinetraffic.com and https://www.vesselfinder.com. On both sites, clicking on a vessel will pull up information about the vessel and it's current travels.

AIS transceiver

A transceiver will both receive signals and transmit signals. This allows you to be seen from some distance, and allows large vessels to change course should you be under sail. I have had numerous encounters with ships, even large tankers, who have diverted their heading when they see me under sail. While this is the rule, it is still a strange sight to see a 1/2 km long vessel weighing hundreds of tons, change course because of my little 15m sailboat. Their propeller blades are bigger than my whole boat.

While transceivers are highly recommended, they can have their drawbacks. Primarily, they not only allow ships to know where you are, but everyone, including some who may have bad intentions.

AIS receiver

A receiver will only receive signals, not transmit any. In our opinion, it is the minimum that you should be fitted with. It receives information from other vessels, in particular, large ships, and displays their position and path on your chart plotter. This allows you to see where they are, and more importantly, where they are going to be. If you only have a receiver it is prudent for you to give way to the larger vessels, as they simply may not see where you are or where you're going.

Our Solution

We have two complete AIS systems onboard. At the top of our mast is a VHF antenna, connected to an AIS transceiver. This unit has a power switch that allows us to turn it off, and thereby "go dark". If we are ever in an area where we wish to remain unseen, the unit is switched off.

Our other unit is an AIS receiver that only receives signals. This allows us to continue monitoring nearby vessels without broadcasting our position.

Hull material. Wood, steel, aluminum or plastic.

Like anchors, there are people who swear that their selection of hull material is the best. I have my opinions (and I swear that my selection of hull material is the best!), and will present them here. These opinions are based on a boat for a post-disaster world.

Wood

The arguments in favour of wood are that it's a renewable resource, and would be repairable at nearly any shoreline.

The arguments against are:

- it must be treated constantly

- it is always going to leak a bit

- repair takes skilled persons

- in tropical climates you'll get wood-worms, which will eat your hull through.

Ferro-Cement

For those who do not know that there are cement boats, it can come as quite a shock. While your first thoughts may be that cement doesn't float, well neither does steel.

It's difficult to assess cement boats as most are home-built. For any type of home-built boat, it's the skill and quality of the build that determines its value. And that is not something you will find out until the vessel fails. Hopefully that's a long way off, and not when you hit a slightly larger than average wave.

I never seriously explored the option, so I can't comment much.

I would presume that if you built it yourself, you'd be able to repair it as well.

Steel

Steel boats are strong. They can survive an impact with most floating debris, and can be beached on sand or even gravel without damage.

They are fairly easy to repair with a welder, as long as you have spare steel.

The biggest failure is that they must be protected from the salt water. They need constant painting to make certain that they don't corrode.

They are also rather heavy.

Aluminum

While lighter than steel, it's otherwise very similar.

Not quite as strong in a collision, nor for beaching, but still fairly rugged.

Welding is possible, but a little more difficult than steel. Again, you need to have a source for aluminum to repair.

Like steel, must be protected from the salt water and needs constant painting to make certain that they don't corrode.

Plastic

Often mislabelled as "fiberglass", the boats are actually GRP, or Glass Reinforced Plastic. There's also carbon fiber, which would be FRP.

Plastic boats have many benefits over the other materials.

- easy to repair. You don't need a lot of skill to repair GRP, just the knowledge and patience to do the job right

- does not need as much maintenance. While having a good bottom paint will inhibit marine growth, your boat won't dissolve below you if you fail to paint it.

- very light. So light that if you get a multi-hull without a weighted keel, they will float even when holed and full of water.

- repair supplies of resin and cloth are quite light and you can carry a good supply for future repairs

Drawbacks include that they are not as strong as metal boats. Hitting a reef can do major damage, while a metal boat may be able to escape. But then again, should both boats get holed the metal one will sink, while a GRP catamaran would remain afloat.

Probably the biggest danger for GRP boats is a collision at sea with debris, like a shipping container. If you're on a cat it won't sink, but you may still need to be rescued from it. While a GRP monohull that hits a floating sea-can will soon be on it's way to visit Davy Jones.

FRP (carbon-fiber) carries all the same traits as GRP, but it's lighter, and stronger than GRP. I have heard it's more difficult to work with and requires greater skill, but I'm sure you could learn it if you had a FRP boat.

Our Solution

If it's not already clear, we went with GRP. FRP would have been nice and we would have done that if we were having the boat built from scratch. However, we used an existing hull to build our boat, so we looked for GRP and found a great one.

Other Points

Here's list of other points I'll be adding and explaining further shortly.

- extra autopilot (mechanical unit)

- SSB radio

- All lines to helm (including lazyjacks)